Description

1. Suitable for all kinds of footwear, such as men's and women's sports shoes, casual shoes, vulcanized

shoes, children's shoes, etc., all models of shoes can be adjusted and used.

2. The operation of this machine is simple and convenient. You only need to put the finished shoes on the last assembly, and the last assembly and push up can be adjusted according to the number of finished shoes. adjust the distance of the component.

3. The machine adopts photoelectric induction type work, and the photoelectric delay time can be set according to the production demand.

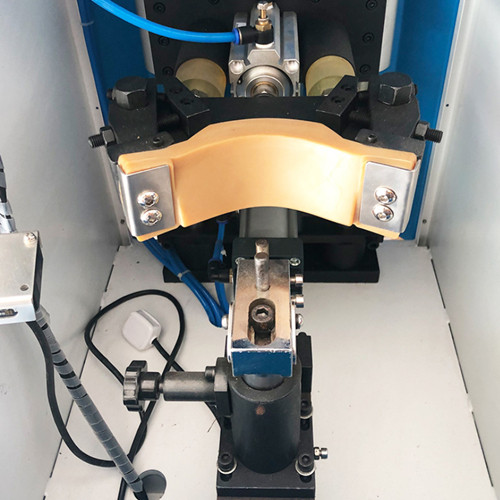

4. The two last-drawing modules of this machine can perform last-drawing operations at the same time or separately, which greatly improves the work efficiency. The display can realize speed regulation, counting, automatic and manual and other functions. The structure design of this machine is simple,occupies a small space.The upper push-pull last component adopts a rubber mold, which has a strong upward and downw ard movement and does not damage the upper.

5. This machine adopts full cylinder operation instead of traditional oil pressure pull last, double-head automatic operation, saving manpower and reducing production cost.

shoes, children's shoes, etc., all models of shoes can be adjusted and used.

2. The operation of this machine is simple and convenient. You only need to put the finished shoes on the last assembly, and the last assembly and push up can be adjusted according to the number of finished shoes. adjust the distance of the component.

3. The machine adopts photoelectric induction type work, and the photoelectric delay time can be set according to the production demand.

4. The two last-drawing modules of this machine can perform last-drawing operations at the same time or separately, which greatly improves the work efficiency. The display can realize speed regulation, counting, automatic and manual and other functions. The structure design of this machine is simple,occupies a small space.The upper push-pull last component adopts a rubber mold, which has a strong upward and downw ard movement and does not damage the upper.

5. This machine adopts full cylinder operation instead of traditional oil pressure pull last, double-head automatic operation, saving manpower and reducing production cost.

| Model | DM-621N |

| Power | 1KW |

| Voltage | 220V/50HZ 1/phase or customized |

| Production | 5000-7000 Pairs/8hours |

| N.W. | 100KG |

| Machine Size | 60*70*130 |